Inspection

Magnetic Particle Inspection

Magnetic Particle Inspection is a non-destructive testing method used to detect surface and near-surface defects in ferromagnetic materials. By applying a magnetic field and magnetic particles, cracks, voids, or other discontinuities become visible, ensuring material integrity and safety.

BHA Inspection

BHA (Bottom Hole Assembly) Inspection involves checking the components of a drilling assembly, including drill bits, stabilizers, and collars, to ensure they are in proper condition and suitable for drilling operations. This inspection helps prevent equipment failure, optimize performance, and maintain safety in drilling operations.

Lifting Inspection

Lifting Inspection involves examining cranes, hoists, and lifting equipment to ensure they are safe, functional, and compliant with industry standards. It helps prevent accidents, equipment failure, and ensures safe handling of loads.

Load Test Inspection

Load Test Inspection evaluates the strength, stability, and performance of equipment, structures, or lifting devices by applying controlled loads. It ensures they can safely handle operational stress and comply with safety standards.

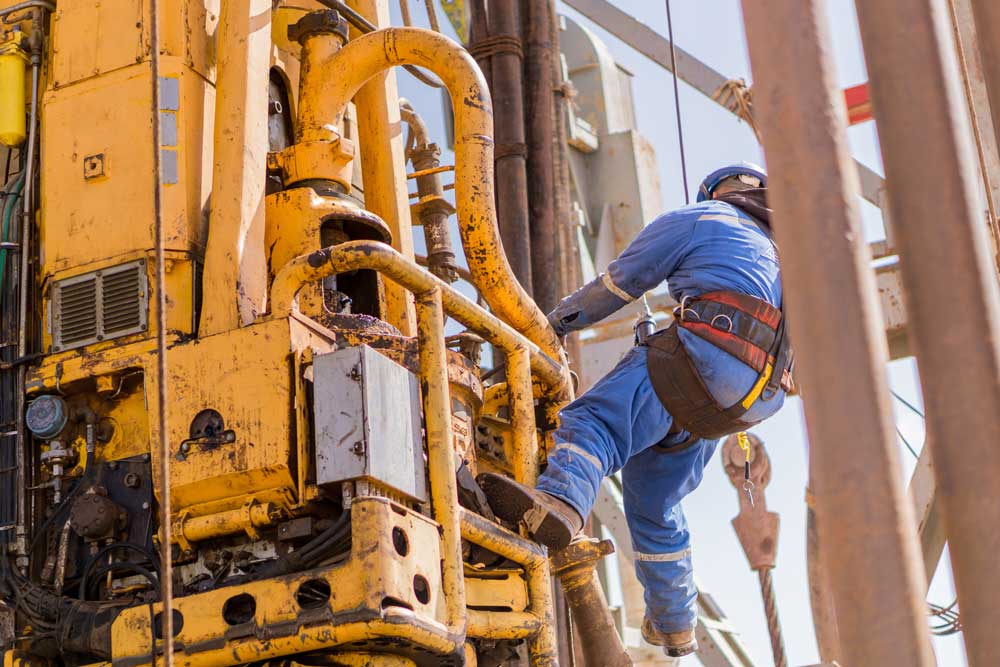

Visual Dynamic Inspection

Visual Dynamic Inspection is a method of examining equipment, machinery, or components while they are in operation. It helps detect defects, wear, misalignments, or abnormal behavior in real-time, ensuring safe and efficient performance.

Ultrasonic Thickness Inspection

Ultrasonic Thickness Inspection is a non-destructive testing method that measures the thickness of materials using high-frequency sound waves. It helps detect corrosion, erosion, or material thinning in pipes, vessels, and structural components, ensuring safety and compliance with industry standards.

Drop Survey Inspection

Drop Survey Inspection evaluates the impact resistance and structural integrity of equipment, pipes, or materials by simulating or measuring drops and shocks. It helps identify weaknesses, prevent damage, and ensure safety and reliability in operations.

Tubular Inspection

Tubular Inspection is a non-destructive testing process used to examine pipes, tubes, and tubular components for defects, corrosion, wear, or structural integrity issues. It ensures safety, reliability, and compliance with industry standards.

Lux Test Inspection

Lux Test Inspection measures the illumination levels in a workspace or area to ensure they meet safety, comfort, and industry lighting standards. Proper lighting improves visibility, reduces eye strain, and enhances overall productivity.

Noise Test Inspection

Noise Test Inspection evaluates the sound levels produced by machinery, equipment, or operations to ensure they comply with safety and environmental regulations. It helps protect workers, reduce noise pollution, and maintain a safe working environment.

Emission Test Inspection

Emission Test Inspection measures the pollutants released from engines, vehicles, or industrial equipment to ensure they comply with environmental regulations and standards. It helps reduce air pollution and maintain operational efficiency.

Hydrotesting Inspection

Hydrotesting Inspection is a method used to check the strength and leak-tightness of pipes, vessels, and pressure equipment by filling them with water and applying pressure higher than their normal operating level. This ensures structural integrity, safety, and compliance with industry standards.